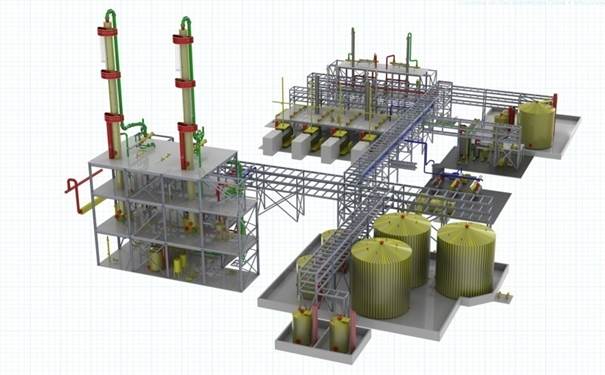

CHEMICALS/PROCESS

Our chemicals/process project portfolio encompasses plastics, polymers and

specialty chemical facilities.

Designing and Building Success

As a recognized industry leader, Lauren has established a successful track record in the Power Generation industry. We approach each project from a whole-asset perspective which enables us to deliver excellence in safety, cost, schedule, quality and overall performance. We work with our clients to maximize their return-on-investment for capital projects to help them better compete in the marketplace. When our clients succeed, we succeed.

Chemicals/Process Capabilities

- Fine And Specialty Chemicals

- Polymers

- Solvent Recovery

- Acids And Anhydrides

- Fertilizer/Ammonia

- Ethanol

- Zinc Recovery

Polymer Expansion

DAK Americas | Charleston, South Carolina

Lauren was responsible for detailed Engineering, Procurement and Construction for this polymer expansion project. The project included the addition of a new 450 ton/day solid stating facility, using proprietary Buhler technology. The project also included the addition of IPA handling and mixing facilities, increasing the capacity of the existing melt phase process, and installation of material handling facilities including storage and railcar loading and unloading. Plant utilities were also upgraded on this project. The work was fixed price and was completed in 14 months.

L1/P3 P.E.T. Resin Expansion

Wellman, Inc. | Bay St. Louis, Mississippi

Lauren provided the Engineering, Procurement and Construction services for Wellman’s Pearl River Plant P.E.T. Resin Expansion, located in Port Bienville Industrial Park, Bay St. Louis, Mississippi. This project included the addition of 300 million pounds of additional solid stating capacity annually to the facility using Buhler technology.

P.E.T. Solid Stating Facility

Tolaram/Buhler | Asheboro, North Carolina

Lauren provided Engineering, Procurement and Construction services for a new P.E.T. solid stating facility at Tiepet’s Asheboro, North Carolina plant. Work included foundations, structures, buildings, access facilities, equipment, piping, electrical and instrumentation.

Polymer Solid Stating Plant

Eastman Chemical Company | Columbia, South Carolina

Lauren was responsible for the design and construction of this Polymer Solid Stating Plant in Columbia, South Carolina. The design was prepared concurrent with construction to support the aggressive schedule for project completion. A new four-level steel-frame process building 9,000 sq.ft. was constructed to house the new process systems. The process equipment scope included the installation of large heaters, reactors, and storage bins in addition to numerous pumps, blowers and cyclones. The product piping systems were large diameter [18” to 60”] low pressure systems made from stainless steel material. All lighting, branch circuits and control wiring systems utilized the extensive cable tray and steel conduit systems. The project was commissioned for operation 13 months after the start of detailed design.

Holston Army Ammunition Plant

BAE Systems | Kingsport, Tennessee

This project, titled “A2B”, involved building a new facility to produce the acetic acid and acetic anhydride for the plant. The facility will consolidate production from area “A” into the main Holston plant site at area “B”. The project marked the largest construction effort at the plant since the original facility was built during WWII.

The project included incoming raw material housing, and shipping and handling warehousing. The process included tanks, heat exchangers, agitation and fluid classification technology.

Adipic Acid Crystallization Expansion

Monsanto Chemical Company | Gonzales, Florida

Lauren was responsible for the design, procurement, and installation of new electrical and instrumentation systems required for the addition of this new process in an existing chemical plant. The new electrical systems included primary power service and branch circuits for new equipment, lighting, and control systems added to the Fisher-Provox DCS. New instrumentation systems required numerous remote mounted devices and PLC’s that are monitored and managed from an existing distributed control system. Lauren supplied and installed all control devices, conduit, cable, fixtures and primary power equipment.

Electric Design and Construction - Vydyne Plant

Monsanto Chemical Company | Pensacola, Florida

Lauren designed and installed the electrical and process control systems for Monsanto’s Vydyne plant in Pensacola, Florida. The work was performed under the terms of a fixed-price contract that was based on conceptual process design for the new facility. The project was commissioned for operation seven months after the start of the installation work.

Solid Stating Facility

KoSa | Salisbury, North Carolina

Lauren was responsible for the Engineering, Procurement and Construction of a new fiber solid stating facility in Salisbury, North Carolina, using proprietary Buhler technology. Work on this fixed-price contract included foundations, structures, buildings, convey systems, equipment, piping, electrical, instrumentation and control systems. This project was completed 12 months after receiving the notice to proceed.

Zinc Kiln

Horsehead Corporation | Rockwood, Tennessee

Horsehead Corporation awarded Lauren a contract for a new kiln for their Zinc reclamation facility in Rockwood, Tennessee. The scope of this work included a new rotary kiln, materials handling and ancillary equipment.

Oxidizer Air Systems Upgrade

Duke Solutions | Kingsport, Tennessee

Lauren provided conceptual Engineering, scope development, detailed Engineering, Procurement, Construction and start-up for upgrades to Eastman Chemical’s TPA oxidizer air system. This project included a new 500 HP air compressor, automating seven existing compressors and computer control and load sharing for 11 compressors. Work on this fixed-price contract included foundation, structures, equipment, piping, electrical, instrumentation and control systems.